What Is Dynamic Balancing?

Dynamic balancing is a process used in engineering and manufacturing to ensure that rotating machinery, such as turbines, engines, or even components like fans or rotors, operate smoothly and efficiently. When a rotating object is out of balance, it can cause vibrations, excess wear and tear on components, and even structural damage.

Dynamic balancing involves the measurement and correction of any imbalance in a rotating system by adding or removing weight strategically. The goal is to distribute the mass of the rotating object in such a way that its center of mass coincides with its axis of rotation. This is typically achieved by attaching counterweights in specific locations around the object.

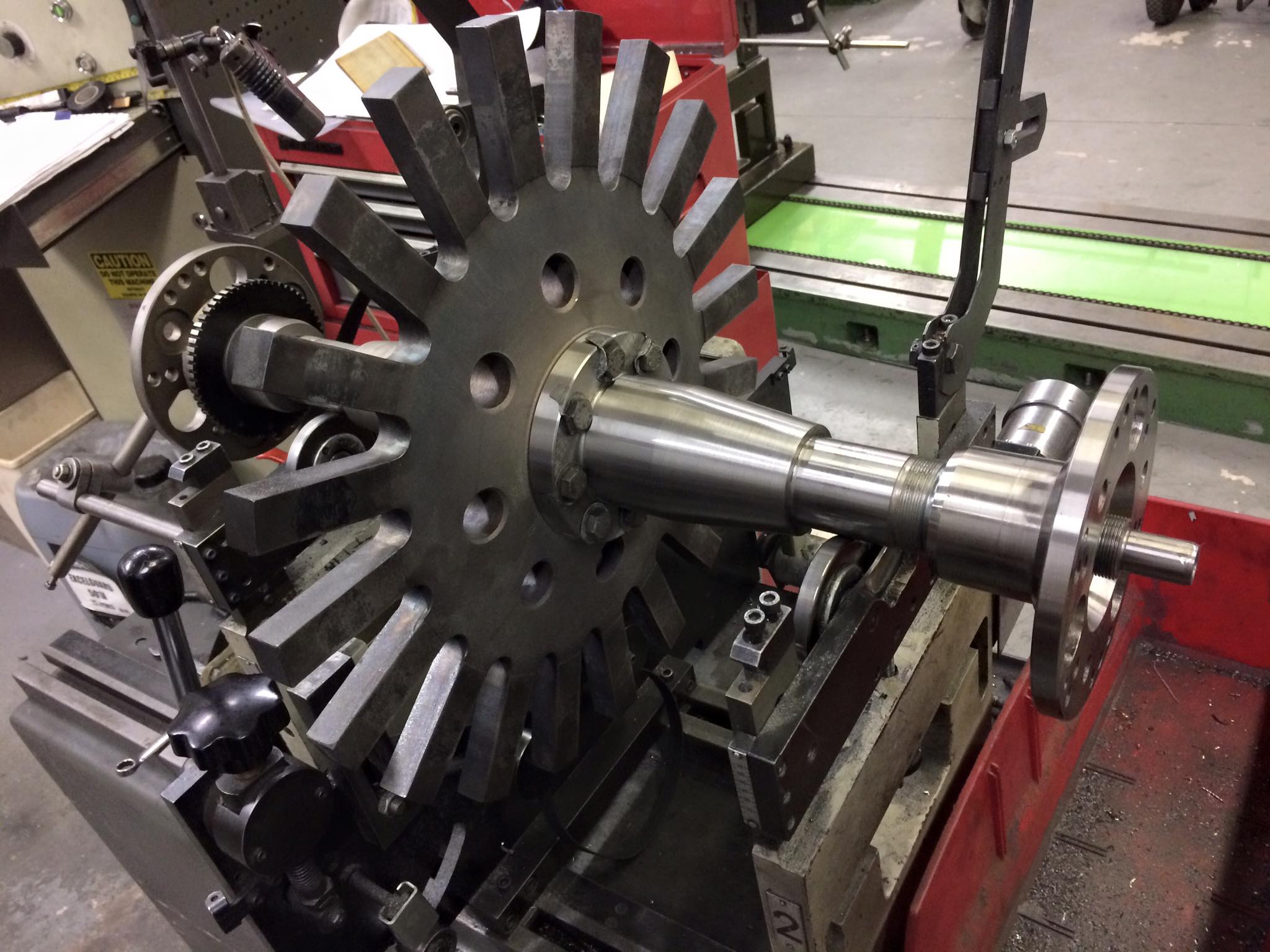

The process usually begins with measuring the amount and location of imbalance using specialized equipment such as vibration analyzers or balancers. Based on these measurements, the technician determines where and how much weight needs to be added or removed to achieve balance.

Dynamic balancing is crucial for ensuring the smooth operation, longevity, and safety of rotating machinery, particularly in industries where precision and reliability are paramount, such as aerospace, automotive, and manufacturing.

Dynamic Balancing in Motorsport

Race engine balancing is a specialized process aimed at optimizing the performance and reliability of high-performance racing engines. It involves carefully balancing the internal components of the engine to minimize vibrations, improve power delivery, and enhance overall efficiency. Here’s how it works:

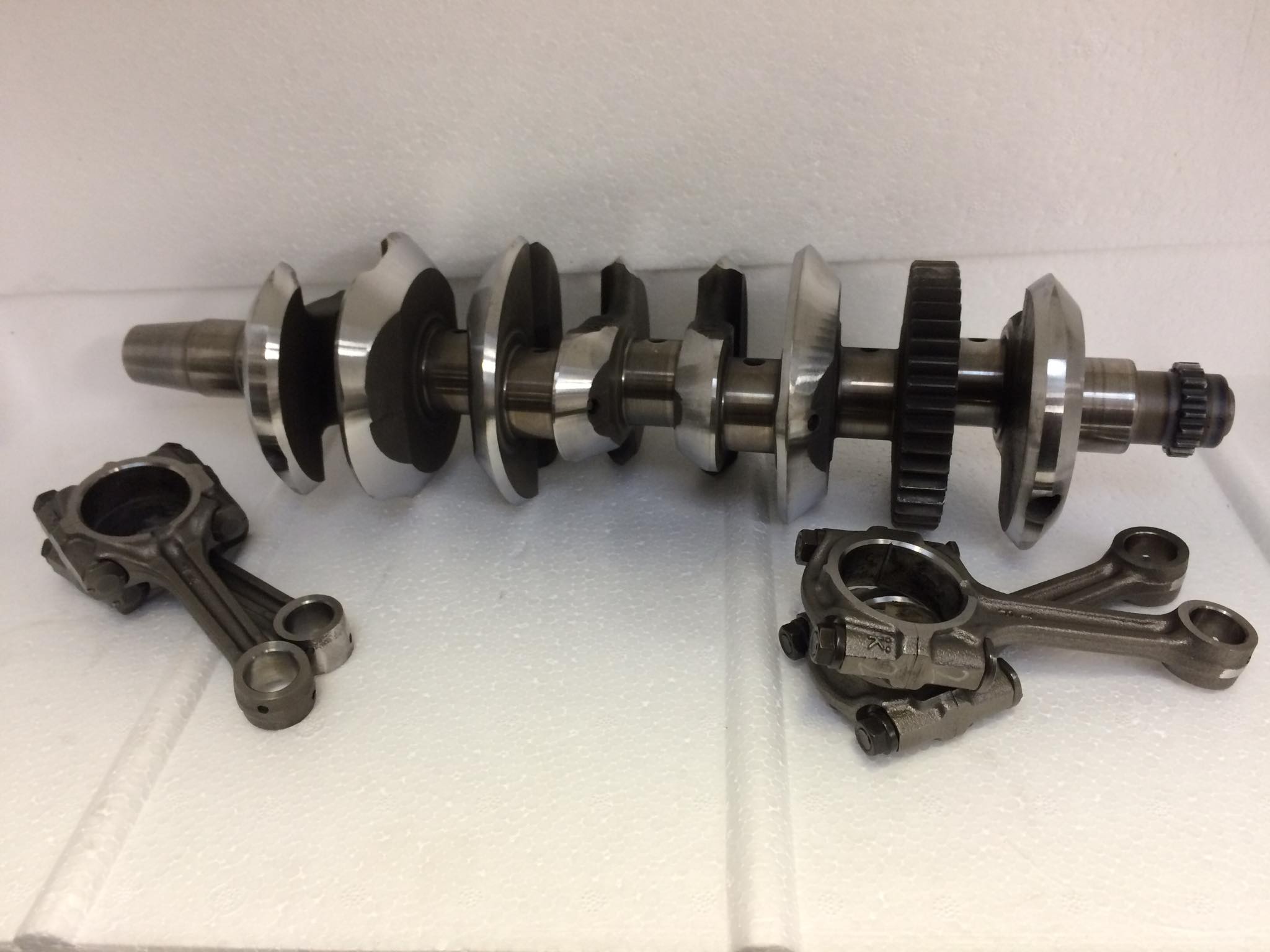

Crankshaft Balancing: The crankshaft is a key component in an engine, responsible for converting the reciprocating motion of the pistons into rotational motion. Balancing the crankshaft involves equalizing the mass distribution around its axis of rotation. This is typically achieved by removing material from specific areas or by adding counterweights to balance out any unevenness. A balanced crankshaft reduces vibration and improves engine smoothness, allowing for higher engine speeds and increased power output.

Piston and Connecting Rod Balancing: Pistons and connecting rods undergo balancing to ensure uniform mass distribution. This involves matching the weight of each piston and connecting rod within a set tolerance. Balancing pistons and connecting rods minimizes vibration and reduces stress on the crankshaft and other engine components, enhancing durability and performance.

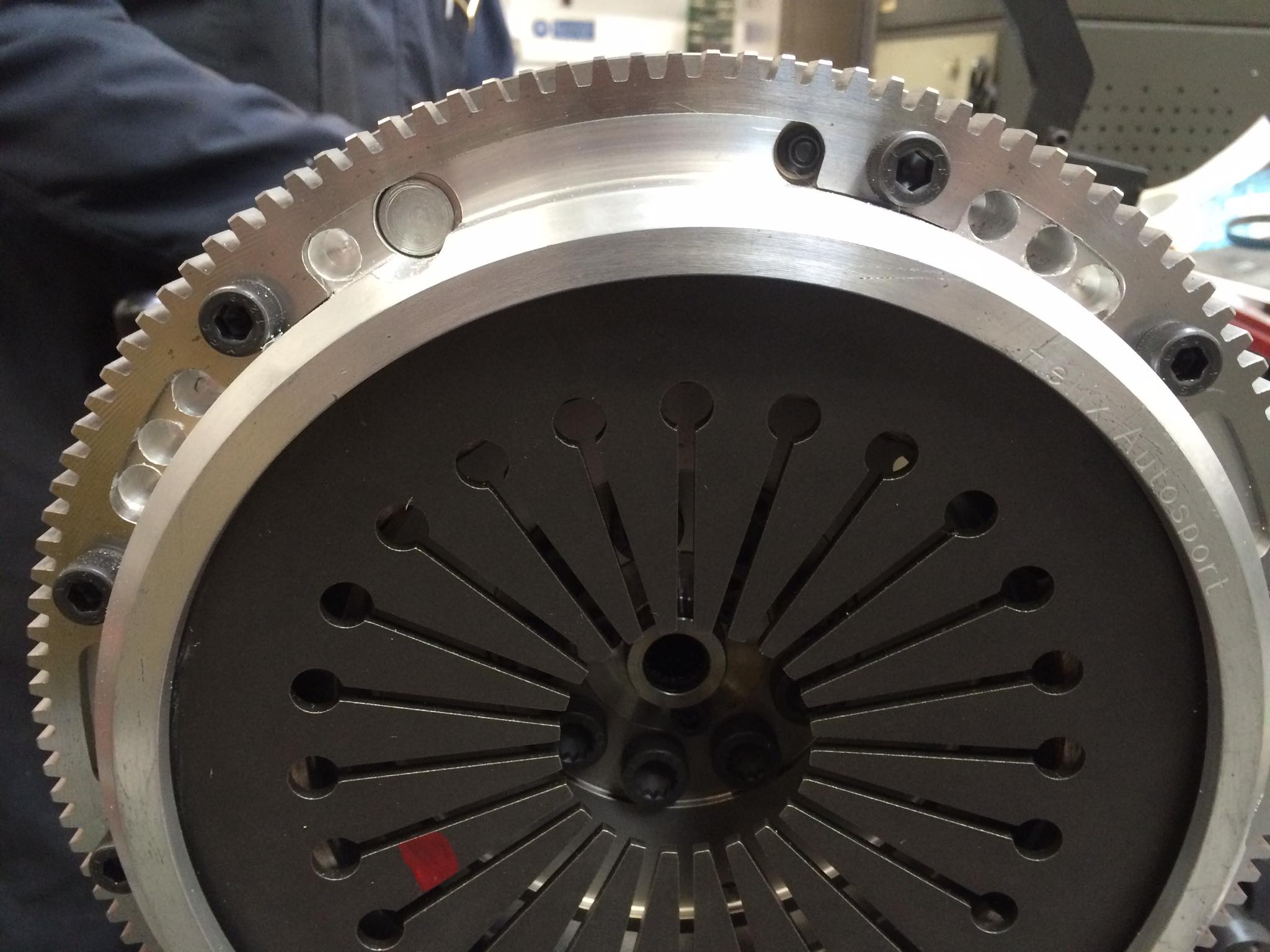

Flywheel and Clutch Balancing: Balancing the flywheel and clutch assembly is crucial for smooth engine operation and precise gear changes. An unbalanced flywheel can cause vibrations and adversely affect engine response, while a balanced assembly ensures consistent performance and improved drivability.

Rotating Assembly Balancing: In high-performance racing engines, the entire rotating assembly, including the crankshaft, pistons, connecting rods, and flywheel, is often balanced as a unit. This comprehensive approach ensures that all rotating components work harmoniously together, minimizing vibrations and maximizing power output.

Dynamic Balancing: Dynamic balancing involves measuring the engine’s vibrations at various speeds and loads and making adjustments as necessary to achieve optimal balance. This iterative process ensures that the engine operates smoothly across its entire operating range, from idle to redline.

Race engine balancing is typically performed by skilled technicians using precision equipment such as dynamic balancers and specialized software. By optimizing the balance of internal engine components, race engine balancing enhances performance, reliability, and drivability, giving racing teams a competitive edge on the track.

Quality

Our in-house Dynamic Balancing service uses the latest technology and certified balancing equipment to provide the highest standards of Dynamic Balancing required within the industry.

All our work is carried out to ISO 9001 specification by our skilled engineers, and we guarantee the highest levels of both attention to detail, and duty of care to our customer’s components.

It is our mission to ensure our quality assurance guarantee affords the peace of mind that only comes with total confidence in a service provider.

Quality

Our in-house Dynamic Balancing service uses the latest technology and certified balancing equipment to provide the highest standards of Dynamic Balancing required within the industry.

All our work is carried out to ISO 9001 specification by our skilled engineers, and we guarantee the highest levels of both attention to detail, and duty of care to our customer’s components.

It is our mission to ensure our quality assurance guarantee affords the peace of mind that only comes with total confidence in a service provider.

Manufacture

We have vast experience in Commercial Balancing encompassing all types of rotating equipment including special purpose machinery, rollers, gear shafts, pulleys and high speed turbine rotors running up to 120,000rpm.

Service industries

Our service is geared to provide a seamless extension to main contractor’s processes.

We provide a complete service to the rewind and breakdown industries. Dynamic Balancing – armatures, rotors, impellors, fans, gears etc. We can accommodate rotors of up to 3 metres in length and 1100mm diameter.

Automotive

AP Balancing are a West Midlands based company who provide a complete balancing service on all crankshaft assemblies, ranging from single cylinder to V16 cranks.

All conrods are balanced end for end and pistons match weighed to within 0.1 of a gram. We specialise in crankshaft knife edging, lightening cranks and Dynamically Balancing them.

Flywheels can be lightened to your own specification for improved engine response.

Automotive

AP Balancing are a West Midlands based company who provide a complete balancing service on all crankshaft assemblies, ranging from single cylinder to V16 cranks.

All conrods are balanced end for end and pistons match weighed to within 0.1 of a gram. We specialise in crankshaft knife edging, lightening cranks and Dynamically Balancing them.

Flywheels can be lightened to your own specification for improved engine response.